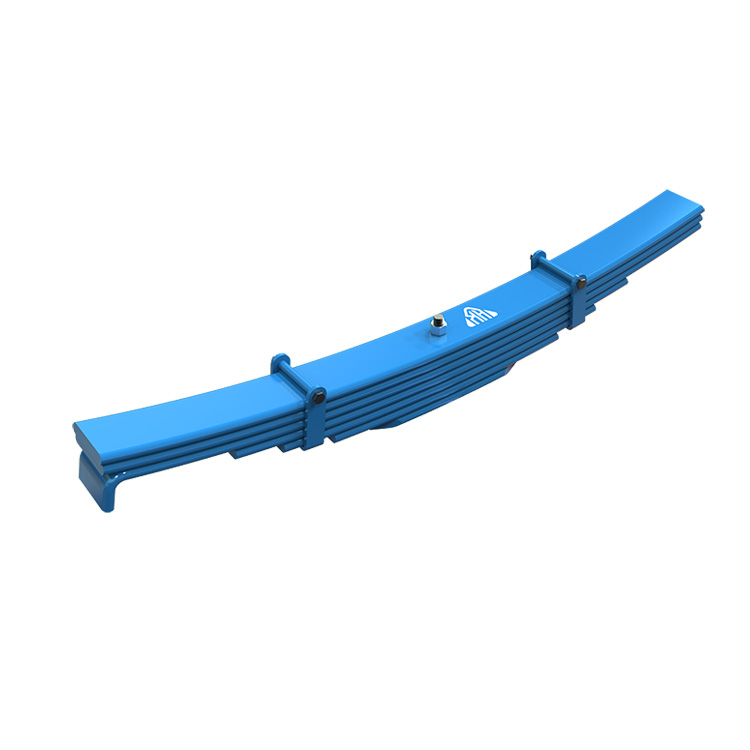

High Quality Leaf Spring

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

A high-quality leaf spring is characterized by several key features and attributes that distinguish it from standard or lower-grade leaf springs. Here are the characteristics that define a high-quality leaf spring:

Material Quality: High-quality leaf springs are typically made from premium materials such as alloy steels or composite materials. These materials offer superior strength, durability, and resistance to fatigue compared to lower-quality steels.

Manufacturing Standards: They are manufactured using advanced processes and stringent quality control measures. This ensures consistency in material properties, dimensional accuracy, and overall performance.

Design Precision: High-quality leaf springs are designed with precision to meet specific performance requirements. This includes optimizing the number of leaves, leaf thicknesses, and lengths to achieve desired load capacities, ride characteristics, and durability.

Durability and Longevity: They are engineered to withstand heavy loads, continuous use, and harsh operating conditions without sagging or deforming over time. High-quality leaf springs maintain their performance and structural integrity over extended periods.

Corrosion Resistance: Special coatings or treatments may be applied to high-quality leaf springs to enhance corrosion resistance. This helps in prolonging the lifespan of the spring and maintaining its performance in diverse environmental conditions.

Weight Optimization: Manufacturers of high-quality leaf springs often employ design strategies to reduce weight without compromising strength or durability. This can contribute to improved fuel efficiency and vehicle handling.

Performance Enhancements: Depending on the application, high-quality leaf springs may incorporate features such as progressive rate leaves, parabolic designs, or integrated damping systems. These enhancements improve ride comfort, handling stability, and suspension performance.

Application Specificity: They are tailored for specific vehicle types, applications (such as heavy-duty trucks, off-road vehicles, or performance cars), and operational requirements. This ensures that the leaf spring is optimized for its intended use, providing maximum benefit in terms of performance and reliability.

Cost Consideration: While high-quality leaf springs may come at a higher initial cost compared to standard springs, they offer superior performance, longevity, and reduced maintenance requirements. This makes them a cost-effective choice over the long term, particularly in demanding or critical applications.

Overall, a high-quality leaf spring combines advanced materials, precise manufacturing, and thoughtful design to deliver enhanced performance, durability, and reliability for various industrial, commercial, and automotive applications.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

High-quality leaf springs find application in a wide range of industries and vehicles where durability, performance, and reliability are paramount. Here are some specific applications:

Commercial Trucks and Trailers:

Heavy-Duty Trucks: High-quality leaf springs are essential components in heavy-duty trucks used for transportation, construction, and logistics. They provide robust suspension systems capable of carrying heavy loads while maintaining stability and ride comfort.

Trailers: Leaf springs are commonly used in trailer suspensions to support payloads and withstand rough road conditions. High-quality leaf springs ensure consistent performance, reducing maintenance costs and downtime.

Off-Road Vehicles:

4x4 Vehicles: Off-road vehicles, such as SUVs and pickup trucks used for recreational or utility purposes, benefit from high-quality leaf springs that offer enhanced durability and superior off-road performance. These springs provide increased ground clearance, improved articulation, and better shock absorption on challenging terrain.

Off-Road Racing: Vehicles competing in off-road racing events require leaf springs that can withstand extreme conditions and provide optimal handling and suspension response. High-quality leaf springs contribute to vehicle stability, traction, and overall performance.

Military and Defense Applications:

Armored Vehicles: Military vehicles, including armored personnel carriers and tactical transport vehicles, rely on high-quality leaf springs to support heavy armor and equipment while ensuring maneuverability and crew comfort in demanding environments.

Logistics Vehicles: Vehicles used for military logistics operations require robust suspension systems to transport supplies and personnel over varied terrain. High-quality leaf springs contribute to vehicle reliability and operational readiness.

Specialty Vehicles and Custom Builds:

Recreational Vehicles (RVs): Motorhomes and RVs use leaf springs to support the vehicle's weight and provide a smooth ride for occupants. High-quality leaf springs enhance comfort, stability, and durability during long-distance travel.

Custom-built Vehicles: Specialty vehicles such as classic car restorations, hot rods, and lifted trucks often incorporate high-quality leaf springs to achieve specific ride heights, handling characteristics, and aesthetic preferences.

Agricultural and Construction Equipment:

Tractors and Agricultural Machinery: Agricultural equipment relies on leaf springs to absorb shocks and vibrations during field operations. High-quality leaf springs improve operator comfort, reduce fatigue, and enhance productivity.

Construction Vehicles: Construction machinery such as excavators, loaders, and dump trucks utilize leaf springs to support heavy loads and withstand rugged construction sites. High-quality leaf springs contribute to equipment reliability and performance.

In each of these applications, high-quality leaf springs play a crucial role in ensuring vehicle or equipment performance, durability, and safety. They are designed and manufactured to meet stringent requirements for load capacity, fatigue resistance, corrosion resistance, and environmental durability, making them indispensable components in various industries and vehicle types.