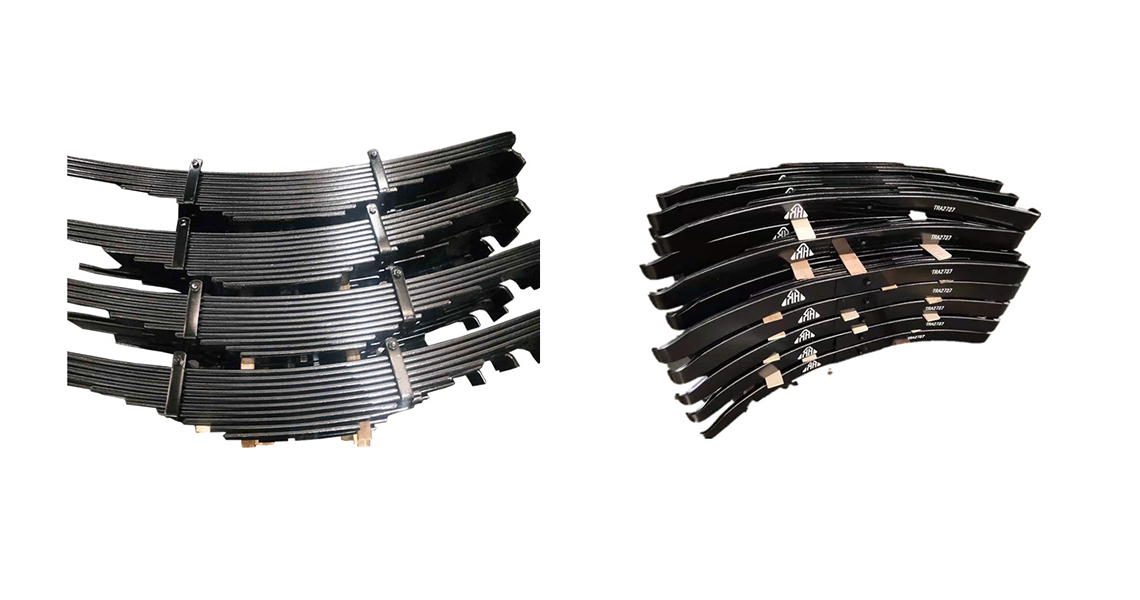

Leaf Spring for Trailer and Truck

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

Leaf springs are utilized in both trailers and trucks primarily for their ability to handle heavy loads effectively and withstand the demanding conditions of transportation. Here’s how leaf springs are applied in trailers and trucks:

Leaf Springs in Trailers:

Load Support: Trailers, whether they are flatbeds, refrigerated units, or specialized trailers, often carry substantial loads. Leaf springs provide the necessary support to distribute the weight evenly across the trailer's axles. This helps in maintaining stability and prevents excessive sagging or bouncing during transportation.

Versatility: Trailers come in various sizes and configurations, each with specific load requirements. Leaf springs can be customized in terms of their design (such as multi-leaf springs) to accommodate different trailer types and weight capacities. This versatility allows manufacturers to tailor the suspension system to meet specific operational needs.

Durability: Trailers are subjected to frequent loading and unloading, as well as exposure to rough road surfaces and varying weather conditions. Leaf springs, typically made from hardened or tempered steel, are designed to withstand these challenges and provide long-lasting performance without significant degradation.

Cost-Effectiveness: Leaf springs offer a cost-effective suspension solution for trailers. They are relatively simple to manufacture and maintain compared to more complex suspension systems, which helps in managing operational costs for fleet operators and logistics companies.

Maintenance: Regular inspection and maintenance of leaf springs are essential to ensure optimal performance and safety. This includes checking for signs of wear, corrosion, and proper lubrication. Timely replacement of worn-out or damaged leaf springs is crucial to prevent safety hazards and maintain the trailer's operational efficiency.

Leaf Springs in Trucks:

Load Handling: Trucks are designed to carry heavy loads over long distances. Leaf springs in trucks provide robust support to distribute the weight of the truck and its cargo evenly across multiple axles. This distribution helps in maintaining stability, controlling vehicle dynamics, and ensuring safe handling on the road.

Suspension System: Leaf springs are a critical component of the truck’s suspension system, working in conjunction with shock absorbers and other components to absorb road shocks and vibrations. This system enhances ride comfort for the driver and helps in reducing wear and tear on the vehicle.

Customization: Similar to trailers, leaf springs in trucks can be customized based on the truck’s weight rating, axle configuration, and specific application requirements. This customization allows manufacturers and truck operators to optimize suspension performance for different types of trucks, whether they are long-haul freight vehicles, regional delivery trucks, or specialty trucks.

Durability and Strength: Truck leaf springs are designed to withstand the demanding conditions of commercial transportation. They are constructed from high-strength materials to ensure durability and reliability under heavy loads and frequent use.

Cost-Effectiveness: Leaf springs provide a cost-effective solution for truck suspension systems. They are robust, relatively easy to maintain, and offer a balance of performance and affordability compared to more advanced suspension technologies like air suspensions.

In summary, leaf springs are essential components in both trailers and trucks, providing critical load support, stability, and durability required for heavy-duty transportation operations. Their versatility, strength, and cost-effectiveness make them a preferred choice in the logistics and trucking industries worldwide.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

Leaf springs are essential components in both trailer and truck applications, playing a crucial role in providing load support, stability, and durability. Here’s how leaf springs are applied and their significance in both contexts:

Leaf Springs in Trailers:

Load Support: Trailers are designed to carry varying loads, from heavy machinery to consumer goods. Leaf springs effectively distribute the weight of the cargo across the axles, ensuring balanced support and minimizing sagging or instability during transportation.

Types and Configurations: Trailers utilize different types of leaf springs based on their load capacity and design requirements. Multi-leaf springs, consisting of several layers of tempered or hardened steel, are commonly used for their ability to handle heavy loads reliably.

Versatility: Leaf springs are versatile and can be tailored to accommodate different trailer types, such as flatbeds, refrigerated trailers, or specialized trailers like tankers or livestock carriers. This adaptability allows manufacturers to optimize suspension systems for specific operational needs.

Durability and Strength: Trailers equipped with leaf springs benefit from their robust construction, which enables them to endure the rigors of frequent loading and unloading, as well as travel over diverse road conditions without compromising performance.

Cost-Effectiveness: Leaf springs offer a cost-effective suspension solution for trailers compared to more complex alternatives like air suspensions. They are relatively simple to manufacture, install, and maintain, contributing to lower operational costs for fleet operators and logistics companies.

Leaf Springs in Trucks:

Load Handling and Distribution: Trucks are tasked with transporting heavy loads over long distances. Leaf springs in trucks play a critical role in evenly distributing the weight across multiple axles, thereby enhancing stability, controlling vehicle dynamics, and ensuring safe handling on the road.

Suspension System Integration: Leaf springs form an integral part of the truck’s suspension system, working in conjunction with shock absorbers and other components to absorb and dampen road shocks and vibrations. This integration enhances ride comfort for drivers and reduces wear and tear on the vehicle.

Customization Options: Similar to trailers, leaf springs in trucks can be customized based on specific truck configurations, load capacities, and operational requirements. This customization allows manufacturers and truck operators to optimize suspension performance for various truck types, including long-haul freight trucks, regional delivery vehicles, and specialized trucks.

Durability and Reliability: Truck leaf springs are designed to withstand the demanding conditions of commercial transportation, providing durability, reliability, and longevity under heavy loads and continuous use.

Maintenance: Regular inspection and maintenance of leaf springs are essential to ensure optimal performance and safety. This includes monitoring for signs of wear, corrosion, proper lubrication, and timely replacement of worn-out components to prevent safety hazards and maintain operational efficiency.

In conclusion, leaf springs are indispensable components in both trailer and truck applications, offering critical benefits such as load support, stability, durability, and cost-effectiveness. Their versatility and strength make them a preferred choice for handling the demanding requirements of heavy-duty transportation in various industries worldwide.