Truck Suspension Parts Leaf Spring

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

Truck suspension systems, particularly those utilizing leaf springs, are critical for supporting heavy loads, ensuring stability, and maintaining control over varied terrain. Here’s an in-depth look at the components and application of leaf springs in truck suspension:

Components of Truck Leaf Spring Suspension:

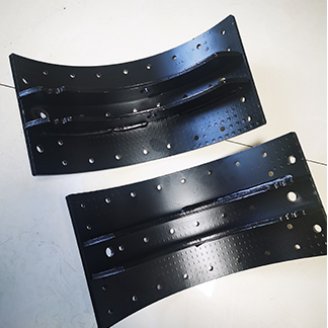

Leaf Springs:

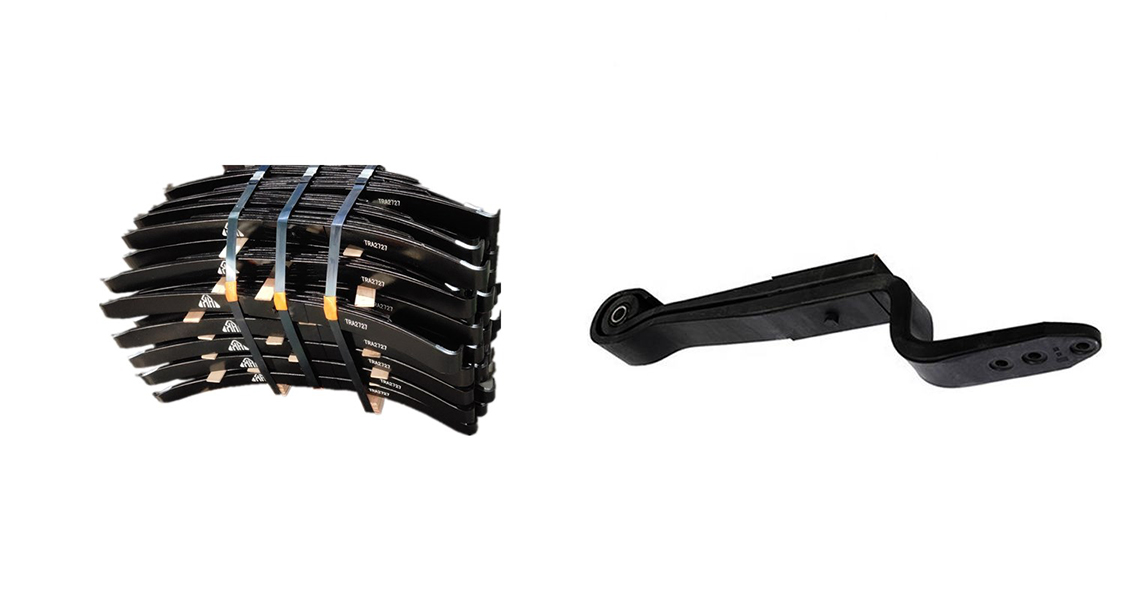

Multi-Leaf Springs: Most trucks use multi-leaf springs, which consist of several layers (or leaves) of tempered or hardened steel stacked together. The main leaf is usually the longest and thickest, with additional leaves stacked on top to provide increased load-carrying capacity.

Mono-Leaf Springs: Some trucks, particularly light-duty and passenger trucks, may use mono-leaf springs, which consist of a single, tapered leaf for simpler suspension configurations.

U-Bolts and Clips:

U-Bolts: These secure the leaf springs to the axle and frame of the truck. They play a critical role in maintaining the alignment and stability of the suspension components.

Clips: Clips are used to secure the individual leaves of multi-leaf springs together. They prevent the leaves from shifting or separating under load.

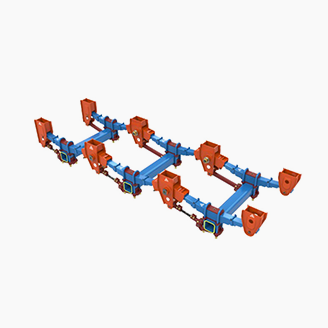

Spring Hangers and Shackles:

Spring Hangers: These are brackets that attach the leaf springs to the frame of the truck. They provide a stable mounting point and allow for the controlled movement of the leaf springs as they compress and rebound.

Shackles: Shackles connect the ends of the leaf springs to the frame or equalizer. They allow for the necessary articulation of the suspension during travel, improving ride quality and reducing stress on the suspension components.

Bushings and Bolts:

Bushings: Bushings are used at the spring eye and shackle connections to reduce friction and allow for smooth movement of the suspension components. They help in absorbing road vibrations and enhancing ride comfort.

Bolts: Bolts secure various suspension components together, ensuring structural integrity and alignment. Proper torque and periodic inspection of bolts are essential for maintaining suspension performance and safety.

Equalizers:

Equalizers: In trucks with multiple axles, equalizers distribute the load evenly between the axles and leaf springs. They help in balancing the suspension forces and improving overall stability and handling.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

Load Handling: Leaf springs are chosen for trucks because of their ability to handle heavy loads effectively. They provide robust support, distributing the weight evenly across multiple axles and ensuring the truck remains stable and balanced under varying load conditions.

Durability and Strength: Leaf springs are known for their durability and strength, making them suitable for the demanding conditions trucks encounter on highways, construction sites, and off-road terrain. They are designed to withstand constant loading and unloading without compromising performance.

Versatility: Leaf springs can be customized in terms of their design and configuration to accommodate different truck models, axle configurations, and load capacities. This customization allows manufacturers to optimize suspension performance based on specific operational requirements.

Cost-Effectiveness: Leaf springs offer a cost-effective suspension solution for trucks compared to more complex systems like air suspensions. They are relatively simple to manufacture, install, and maintain, contributing to lower operational costs for fleet operators and trucking companies.

Maintenance: Regular inspection and maintenance of leaf springs are crucial for ensuring optimal performance and safety. This includes checking for signs of wear, corrosion, proper lubrication, and timely replacement of worn-out components to prevent safety hazards and maintain efficient operation.

In summary, leaf springs play a vital role in truck suspension systems by providing essential load support, stability, and durability required for safe and efficient transportation. Their integration with other suspension components ensures reliable performance across various operating conditions, contributing to the overall functionality and longevity of trucks in commercial and industrial applications.