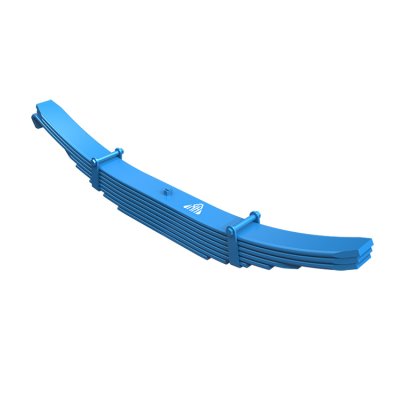

Good Function Leaf Spring

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

Leaf springs have been a foundational component of vehicle suspension for centuries, known for their simplicity and effectiveness in managing vehicle loads and road irregularities. Originally referred to as laminated or carriage springs, they have evolved into various forms like semi-elliptical, elliptical, or cart springs.

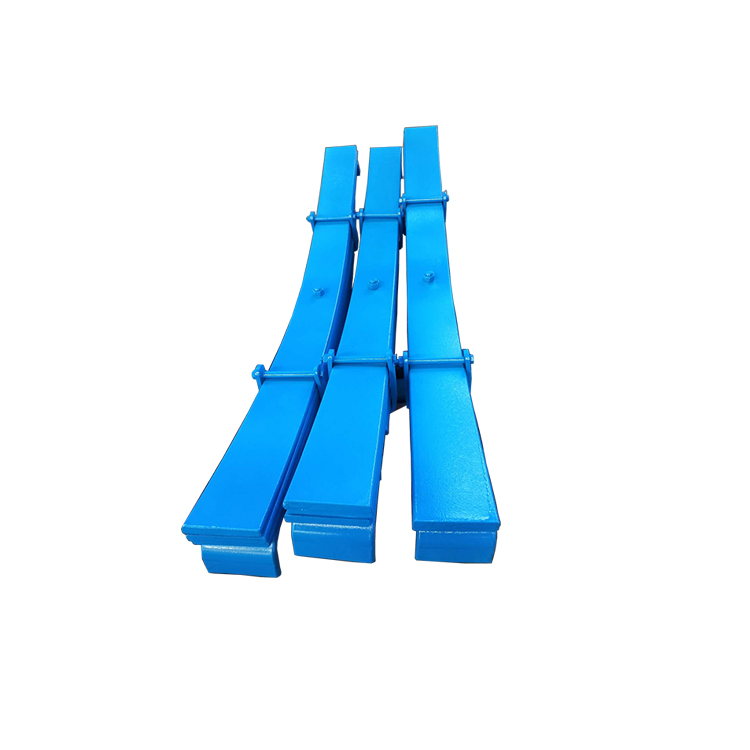

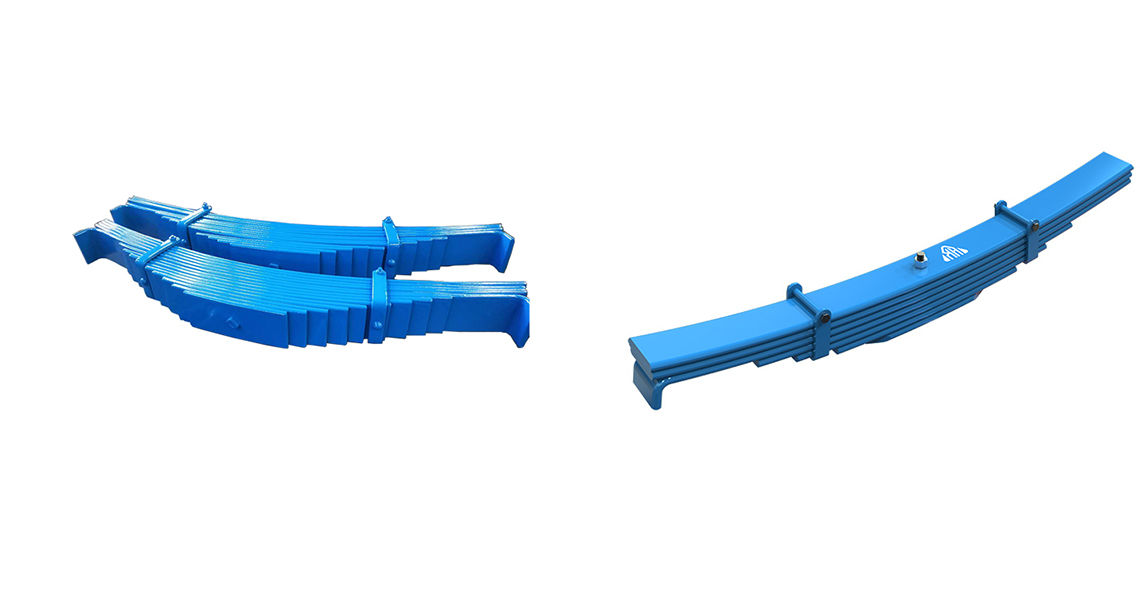

Structure and Functionality:Leaf springs are typically composed of multiple narrow, arc-shaped plates (leaves) of varying lengths, stacked together and attached to the vehicle's chassis at one end and the axle at the other. This arrangement allows the leaf spring to flex vertically, absorbing shocks and vibrations from the road surface. Lateral leaf springs are the most common type, running parallel to the vehicle's length and mounted perpendicular to the axle. However, transverse leaf springs, which run across the vehicle, are also used in some applications.

Suspension Functions:Leaf springs perform several critical suspension functions:

Location: They hold the axle in place relative to the chassis, preventing excessive movement.

Springing: They act as the primary springs, supporting the weight of the vehicle and providing elasticity to absorb bumps and vibrations.

Damping: Leaf springs also contribute to damping characteristics through interleaf friction. When the leaves rub against each other during compression and rebound, friction occurs, which helps dampen the oscillations of the suspension.

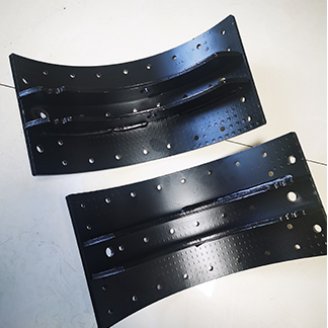

Challenges with Traditional Leaf Springs:One significant challenge with traditional multi-leaf springs is the inherent friction between the leaves. This friction, while contributing to damping, is not well controlled and can lead to issues like stiction and irregular suspension motions. Stiction refers to the resistance to motion during the initial stages of movement, which can affect the smoothness and responsiveness of the suspension.

Mono-Leaf Springs as an Alternative:To address these challenges, some manufacturers have developed mono-leaf springs. Mono-leaf springs consist of a single, thicker leaf instead of multiple thin leaves stacked together. By eliminating the multiple interfaces where friction occurs, mono-leaf springs reduce stiction and provide smoother suspension movement. This design refinement can result in improved ride comfort, better handling characteristics, and potentially lower maintenance requirements compared to traditional multi-leaf springs.

In summary, while leaf springs in their traditional form have served vehicles well for centuries, innovations like mono-leaf springs demonstrate ongoing efforts to enhance suspension performance by addressing friction-related issues and improving overall ride quality.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

Leaf springs indeed play a crucial role in vehicle suspensions across a wide range of applications, from light-duty trucks to heavy-duty trailers and agricultural vehicles. They are known for their durability and ability to handle substantial loads, making them ideal for vehicles that frequently encounter rough terrain or heavy payloads.

Here’s a breakdown of some common types of leaf springs mentioned:

Conventional Leaf Springs: Traditional leaf springs consisting of several alloy spring leaves clamped together.

Parabolic Leaf Springs: These have a tapered, parabolic shape which provides a more flexible and smoother ride compared to conventional leaf springs.

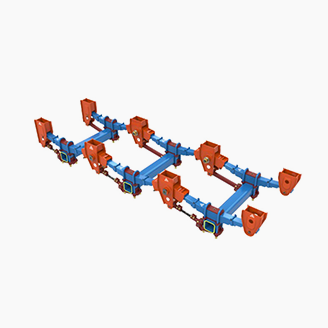

Z Type Air Linkers: This type of suspension typically incorporates air springs in a Z-shaped configuration, offering adjustable ride height and load support.

TRA Leaf Springs: Specifically designed for trailers, these leaf springs are tailored to handle the unique load characteristics of trailer suspensions.

Light Duty Trailer Springs: Optimized for lighter trailers where weight and flexibility are critical factors.

Boat Trailer Springs: Designed to support and cushion boat trailers, which often have unique weight distribution and load characteristics.

Pickup Leaf Springs: These are tailored for pickup trucks, balancing load capacity with ride comfort.

Semi Trailer Springs: Heavy-duty springs for semi-trailers, which need to support significant loads over long distances.

Truck Springs: General term for leaf springs used in various types of trucks, ranging from light-duty to heavy-duty applications.

Agricultural Trailer Springs: Specifically designed for agricultural trailers, which may need to traverse rough, uneven terrain.

Bus Springs: Leaf springs used in bus suspensions, designed to provide comfort and stability for passenger transport.

Bogie/Boogie Springs: Springs used in bogie suspensions, which are crucial for railway rolling stock and some heavy-duty trailers.

Each type of leaf spring is engineered to meet specific requirements regarding load capacity, ride comfort, durability, and adaptability to different vehicle designs and applications. The versatility of leaf springs makes them a cornerstone of suspension systems in various industries, ensuring that vehicles can operate safely and effectively under diverse conditions.

FAQ:

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.