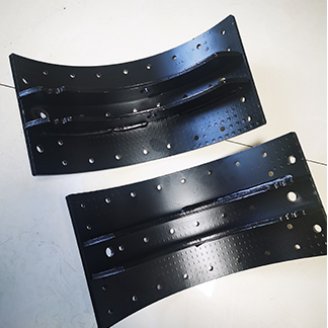

Brake Shoe for Truck

20+ years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality testing by an independent laboratory

Warranty: 12 months since shipping date

Sales volume (units) : 1,000,000+

Brake shoe: cylindrical grinding

Customized packaging:Acceptable

Truck brake shoes are essential components of the braking system in trucks. Here's some key information about them:

1. Function: Brake shoes are part of the drum brake system, which is common in heavy vehicles like trucks. When you press the brake pedal, hydraulic pressure pushes brake shoes against the inner surface of the brake drum, creating friction that slows down and stops the truck.

2. Construction: They are typically made of heat-resistant friction material bonded or riveted to a metal backing plate. This friction material is designed to withstand the heat generated during braking and provide consistent performance over time.

3. Replacement: Brake shoes wear out over time due to the friction generated during braking. Regular inspection and replacement are necessary to maintain braking efficiency and safety. The replacement interval depends on factors such as driving conditions, load, and driving habits.

4. Maintenance: Proper maintenance of brake shoes involves periodic inspection of the brake system, including checking the thickness of the friction material and ensuring that the brake drums are within specified tolerances. Any signs of wear or damage should prompt immediate replacement.

5. Safety: Maintaining the braking system, including the brake shoes, is crucial for the safety of the truck and its occupants. Properly functioning brakes ensure reliable stopping power and reduce the risk of accidents.

6. Professional Service: Replacing brake shoes is often done by trained mechanics due to the complexity of the brake system and the importance of proper installation. It's recommended to have brake shoes replaced at a certified service center or by a qualified technician.

Replacements | Benz Mp31 Cast Mp32 Cast Mp36 Cast |

Brake sizes | 420×150 mm, 420×180 mm, 420×200 mm, 420×220 mm, 311×190 mm, etc. |

Colors | Red, black, grey, blue, etc. |

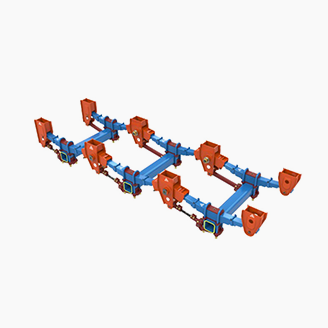

Optional parts | Brake lining, rivet, repair kit of brake shoe, etc. |

Package | Pallet. |

Standards implemented | IATF 16949, ISO9001-2015, JT/T 475-2020 |

Payment | TT, LC, DP |

Lead time | About 10~15 working days |

MOQ | 1 unit |

Application:

The application of truck brake shoes refers to the process of installing or replacing brake shoes on a truck's braking system. Here are the key aspects of this process:

1. Understanding Brake Shoes: Brake shoes are components of drum brake systems. They are curved metal plates lined with friction material (such as asbestos, ceramic, or semi-metallic compounds) that press against the brake drum to slow or stop the vehicle.

2. When to Replace Brake Shoes: Brake shoes wear down over time due to friction. Signs that brake shoes need replacement include reduced braking efficiency, squealing noises while braking, or visible wear on the shoes themselves.

3. Tools and Equipment Needed: Common tools required for brake shoe replacement include a jack and jack stands (or a lift), lug wrench, pliers, brake spring pliers, brake spoon adjuster, and a brake cleaner.

4. Step-by-Step Application Process:

- Jack up the Truck: Secure the truck on jack stands or a lift, ensuring safety.

- Remove the Wheels: Use a lug wrench to remove the lug nuts and take off the wheels.

- Access the Brake Assembly: Locate the brake drum and remove it to access the brake shoes.

- Inspect and Replace: Inspect the brake shoes for wear. Replace them if they are worn beyond safe limits.

- Install New Brake Shoes: Install new brake shoes by reversing the removal process. Use brake spring pliers to handle the springs safely.

- Adjust and Reassemble: Adjust the brake shoe position using the brake spoon adjuster if necessary. Ensure all parts are securely reassembled.

- Test Brakes: Before driving, pump the brake pedal to adjust the shoes. Test the brakes in a safe, controlled environment to ensure proper operation.

5. Safety Considerations: Always prioritize safety when working on brakes. Use appropriate tools, follow manufacturer guidelines, and consider professional assistance if unsure about any steps.

6. Maintenance: Regularly inspect and maintain brake shoes as part of routine vehicle maintenance to ensure safe braking performance.

By following these steps and considerations, you can effectively apply truck brake shoes, maintaining the safety and reliability of the braking system.

FAQ

Q: What are your advantages?

A: We are a professional supplier with nearly twenty years, always putting quality and price in the first place. Meanwhile, our products are exported to many countries, and we have rich experience in solving tricky problems.

If you want to know more about our products and ourselves, you are welcome to send me an e-mail for consultation!

Q: How long is your quality assurance period?

A: Our warranty period is 12 months after we receive the goods. During the warranty period, we will provide free repair and replacement of parts damaged due to quality issues.

Q: What is the usual packaging?

A: Neutral Packing: Box + Carton + Pallet

Plastic bag + carton + pallet

Plastic bag + pallet

Different products have different packaging. In addition, customized cartons are also available.

Q: What are the payment methods?

A: TT,LC,DP,ect