Leaf Spring for Trailer

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product description:

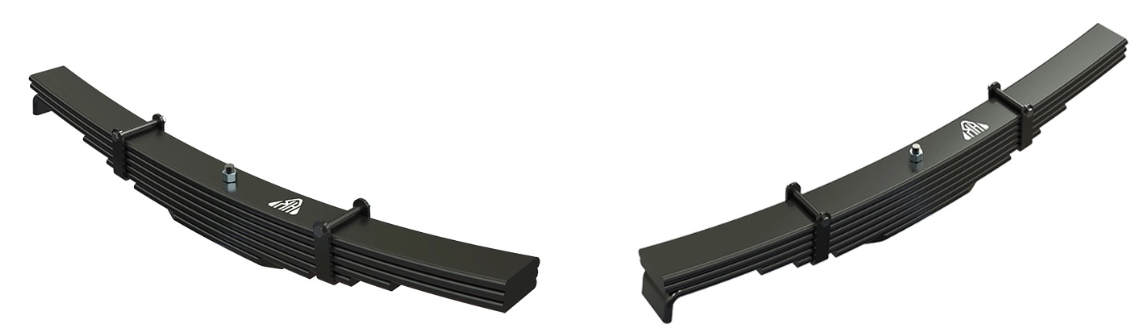

A leaf spring is a simple form of spring commonly used for suspension in wheeled vehicles. Originally called a laminated or carriage spring, and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates that are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of transverse leaf springs exist as well.

Leaf springs can serve multiple suspension functions: location, springing, and to some extent damping as well, through interleaf friction. However, this friction is not well controlled, resulting in stiction and irregular suspension motions. For this reason, some manufacturers have used mono-leaf springs.

Product parameters:

Model | Parameters | Symbols | Chord length(mm) | Arc height(mm) | Number of pieces | Sheet thickness(mm) | Width (mm) | Weight per stack (kg) |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

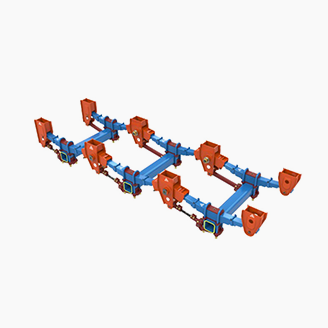

Application:

A leaf spring is the most widely used elastic element in automobile suspensions.

It is an approximate equal strength steel beam composed of several alloy spring sheets of equal width and unequal length. Its main function is to transmit all forces and moments between wheels and frames, relax impactive load caused by the road surface and realize vehicle guidance, make vehicles normal drive.

Leaf springs are widely applied to suspensions for heavy duty trucks, light duty trucks, pick-ups, cars, skeletal trailers, lowbed trailers, flatbed trailers, oil tank trailers, van trailers, wood transport trailers, gooseneck trailers, agricultrucal vehicles, etc. Classification of Leaf Springs include Conventional leaf springs, parabolic leaf springs, Z type air linkers, TRA leaf springs, trailer leaf springs,light duyt trailer spring, boat trailer springs, pickup leaf springs, semi trailer springs, truck springs, farming/agricultural trailer springs, sprung drawbar, bus springs, bogie/boogie springs, heavy truck springs, etc.