Leaf Spring

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

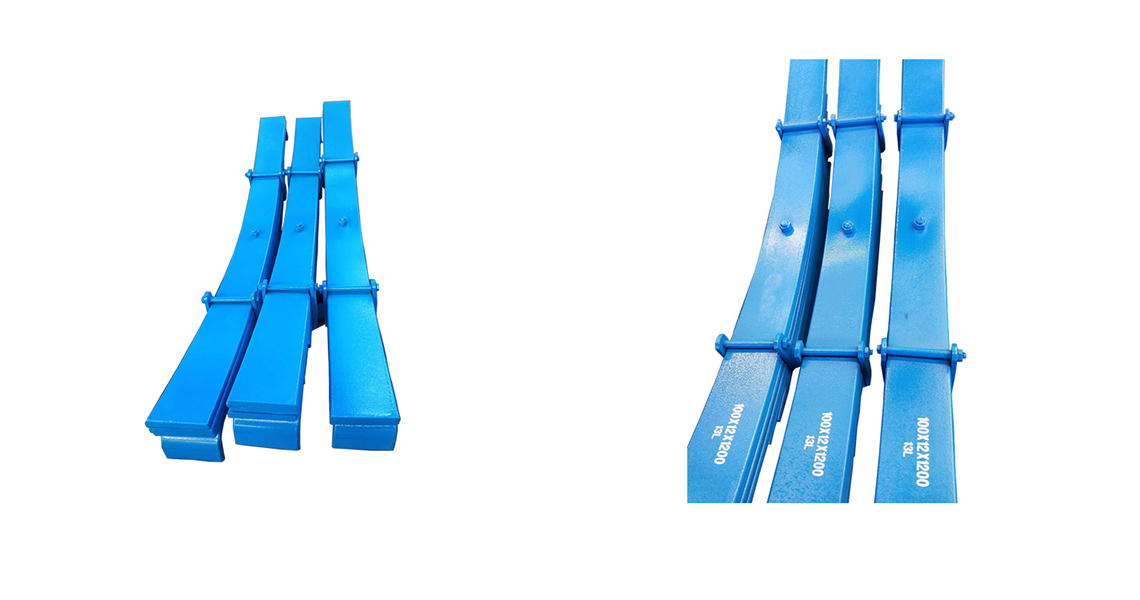

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

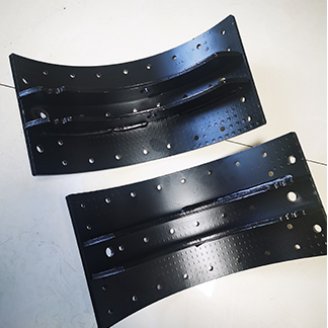

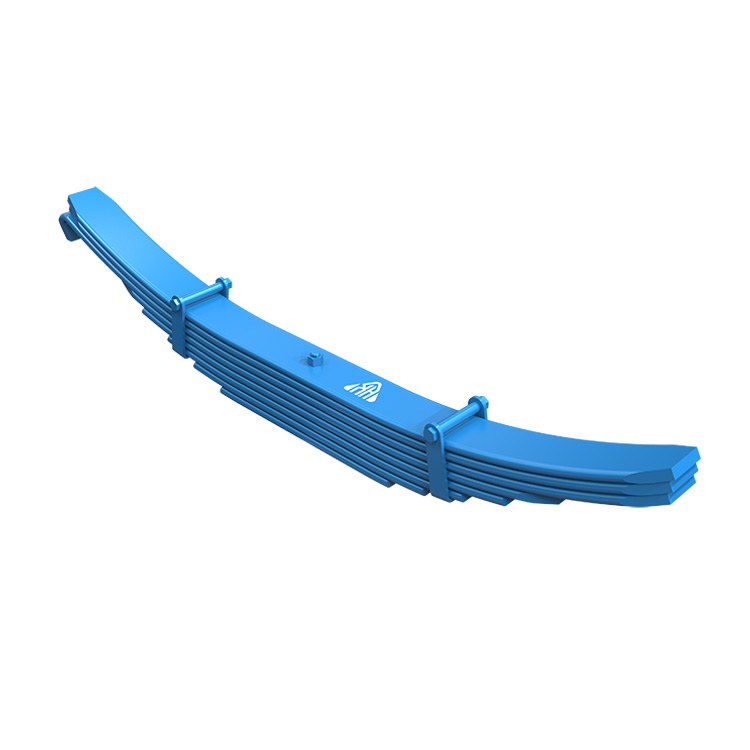

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. It consists of a series of curved, narrow, flat plates or "leaves" of varying lengths stacked on top of each other. These leaves are held together in the center by a bolt or clamp and are attached at both ends to the vehicle frame and axle.

The primary function of a leaf spring is to absorb and distribute the weight and shocks encountered during vehicle movement. When the wheel encounters bumps or uneven terrain, the leaf spring flexes and absorbs the impact, providing a smoother ride and reducing stress on the vehicle chassis.

Leaf springs are known for their durability and ability to carry heavy loads, which makes them suitable for trucks, trailers, and some older passenger vehicles. However, they can be less flexible and provide a rougher ride compared to more modern suspension systems like coil springs or air suspension.

In modern vehicles, leaf springs are less commonly used in favor of other suspension designs that offer better ride comfort and handling characteristics.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

Leaf springs have been widely used in various applications due to their simplicity, durability, and ability to handle heavy loads. Here are some common applications of leaf springs:

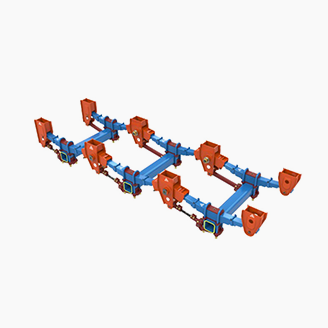

Automotive Suspension: Leaf springs were historically used in the suspension systems of trucks, buses, and some older passenger vehicles. They provide robust support for carrying heavy loads and are relatively inexpensive to manufacture.

Trailer Suspension: Leaf springs are commonly used in the suspension systems of trailers, including utility trailers, boat trailers, and caravan trailers. They help absorb shocks and vibrations during towing, ensuring a smoother ride for the cargo.

Railroad Cars: Leaf springs are also used in railroad cars, particularly for freight cars. They help to support the weight of the cargo and absorb shocks and vibrations encountered during rail transportation.

Agricultural Equipment: Leaf springs can be found in various agricultural equipment such as plows, harrows, and wagons. They provide support and stability, especially in rough and uneven terrains.

Industrial Applications: Leaf springs are used in industrial equipment and machinery where there is a need for heavy load-bearing capabilities and shock absorption. They are commonly found in crane trucks, forklifts, and off-road vehicles.

Military Vehicles: Military vehicles often use leaf springs due to their ruggedness and ability to withstand harsh conditions. They are employed in trucks, armored vehicles, and military trailers.

Despite advancements in suspension technology, leaf springs continue to be used in many applications where their strengths — simplicity, durability, and load-carrying capacity — outweigh their limitations in terms of ride comfort and flexibility.