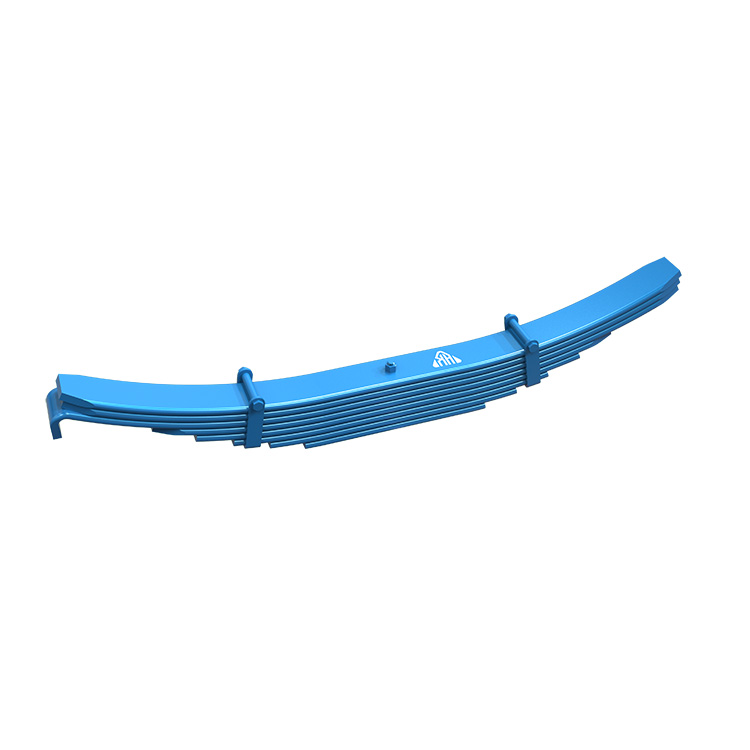

Heavy Duty Truck Leaf Spring

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

Heavy-duty truck leaf springs are crucial components in a vehicle's suspension system, especially for trucks and other heavy-duty vehicles. They help support the vehicle's weight, absorb shocks, and maintain stability and control.

Here’s a bit more detail on them:

Design and Function:

Leaf Spring Structure: They consist of several layers (or leaves) of metal, typically spring steel, stacked together. The layers are curved and held together with clamps. The spring's curvature and the number of leaves affect its strength and flexibility.

Function: When the truck encounters bumps or uneven surfaces, the leaf springs compress and flex to absorb the impact. This helps to keep the vehicle's load stable and improve ride comfort.

Types:

Mono-Leaf Springs: Made from a single leaf, these are generally used in lighter-duty applications.

Multi-Leaf Springs: Consist of multiple leaves and are used in heavier-duty applications. They provide greater strength and durability.

Benefits:

Durability: Leaf springs are known for their durability and longevity, which makes them ideal for heavy-duty applications.

Load Distribution: They help distribute the vehicle's load evenly, which is crucial for maintaining balance and stability.

Shock Absorption: They effectively absorb shocks from the road, which helps to protect the truck's cargo and improve ride comfort.

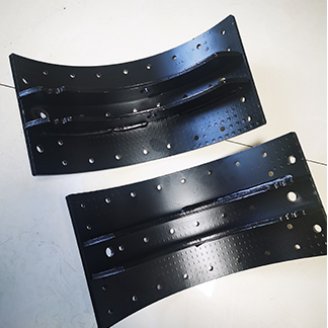

Maintenance and Replacement:

Inspection: Regular inspections are necessary to check for signs of wear, such as cracks or excessive rust. Damaged or worn-out leaf springs can lead to poor handling and increased wear on other suspension components.

Replacement: If a leaf spring is damaged, it’s crucial to replace it promptly to maintain vehicle safety and performance. Replacement involves removing the damaged spring and installing a new one, which can be done by a professional mechanic.

Customization:

Load Capacity: Leaf springs can be customized to handle specific loads. For instance, adding extra leaves or upgrading to a stronger material can enhance their load-bearing capacity.

Lift Kits: They can also be part of lift kits to raise the truck’s height, which is often done for off-roading purposes or to accommodate larger tires.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

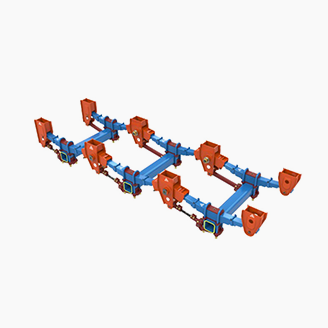

Heavy-duty truck leaf springs are used in various applications where robust suspension systems are needed to handle substantial loads and tough conditions. Here’s a breakdown of their primary applications:

1. Commercial Trucks

Cargo Hauling: In commercial trucks, leaf springs are essential for supporting heavy loads. They provide the necessary strength to handle the weight of cargo and ensure a stable ride.

Delivery Trucks: For trucks that make frequent stops and starts, leaf springs absorb the shocks from loading and unloading, enhancing overall stability and reducing wear on the vehicle.

2. Construction Vehicles

Dump Trucks: These trucks use heavy-duty leaf springs to support the substantial weight of the payload, including construction materials like sand, gravel, or debris.

Cranes and Excavators: Heavy-duty leaf springs are also used in vehicles that support heavy machinery or equipment, ensuring stability and effective shock absorption during operation.

3. Agricultural Vehicles

Tractors: In agricultural machinery, leaf springs help manage the weight of both the vehicle and any attached implements or equipment, providing a smoother ride over rough terrain.

Harvesters: These vehicles, which deal with significant loads of crops, rely on robust leaf springs to ensure smooth operation and durability.

4. Off-Road Vehicles

4x4 Trucks: Leaf springs are commonly used in off-road trucks for their durability and ability to handle rough and uneven terrain. They help provide clearance and stability in challenging conditions.

All-Terrain Vehicles (ATVs): For ATVs and utility vehicles, leaf springs contribute to load-bearing capacity and shock absorption in rugged environments.

5. Military Vehicles

Armored Vehicles: Military trucks and armored vehicles use heavy-duty leaf springs to support heavy armor and equipment while maintaining maneuverability and performance.

Logistics Vehicles: In logistics operations, leaf springs are crucial for handling the weight of supplies and equipment transported in various military vehicles.

6. Recreational Vehicles

Camper Trailers: Leaf springs in camper trailers and RVs help manage the weight of the living quarters and ensure a smoother ride, particularly over uneven or off-road surfaces.

Boat Trailers: Heavy-duty leaf springs are used in boat trailers to support the weight of the boat and ensure safe and stable towing.

7. Emergency Vehicles

Fire Trucks: Heavy-duty leaf springs in fire trucks support the weight of firefighting equipment and water tanks, ensuring that the vehicle remains stable while in operation.

Ambulances: For ambulances, leaf springs help manage the weight of medical equipment and provide a smooth ride for patient transport.

8. Specialized Applications

Tow Trucks: These vehicles use heavy-duty leaf springs to handle the weight of both the truck itself and the vehicles being towed.

Mobile Cranes: For mobile cranes, leaf springs are critical in supporting the weight of the crane and its load, while maintaining stability during operation and transport.

In all these applications, heavy-duty leaf springs provide the necessary support and durability to handle the demands of the job, ensuring safe and efficient operation in various conditions.