Trailer and Truck Leaf Spring

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

Leaf springs are a crucial component of both trailers and trucks, designed to support and cushion the load while maintaining vehicle stability. Here's a brief overview of their function and importance:

Function of Leaf Springs:

Load Support: Leaf springs help distribute the weight of the load evenly across the vehicle's axle, which helps prevent excessive wear and tear on the suspension system.

Shock Absorption: They provide a degree of shock absorption, smoothing out the ride by absorbing and dissipating impacts from the road.

Vehicle Stability: By keeping the axle in proper alignment and allowing for some flex, leaf springs help maintain vehicle stability and control.

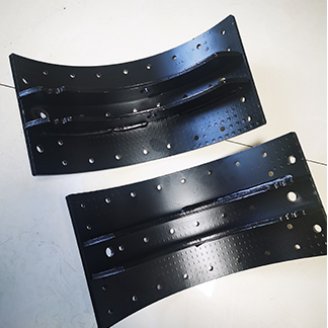

Leaf Spring Design:

Construction: Leaf springs are typically made of several layers of metal, called leaves, which are stacked together. They can be found in varying lengths and thicknesses depending on the vehicle's requirements.

Configuration: They are usually mounted above or below the axle, with the ends attached to the vehicle’s frame. As the vehicle moves, the leaves flex and compress to absorb road irregularities.

Differences Between Trailer and Truck Leaf Springs:

Truck Leaf Springs:

Heavy-Duty: Designed to handle heavier loads and rougher terrain, making them robust and durable.

Performance: They might feature additional layers or specially engineered designs to enhance performance and stability.

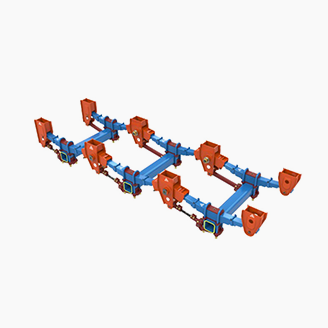

Suspension Types: Trucks often use a combination of leaf springs and other suspension components like shock absorbers and stabilizers.

Load Bearing: While also strong, trailer leaf springs are designed primarily to support the weight of the trailer and its cargo.

Flexibility: They might be designed with a greater degree of flexibility to accommodate various types of cargo and road conditions.

Simplicity: Trailer suspensions might be simpler compared to truck suspensions, focusing on durability and ease of maintenance.

Maintenance Tips:

Regular Inspection: Check for signs of wear, such as cracks or rust, which can compromise the integrity of the leaf springs.

Lubrication: Some leaf springs have bushings that require lubrication to prevent noise and wear.

Alignment Check: Ensuring proper alignment is crucial for maintaining vehicle stability and even tire wear.

If you’re experiencing issues with your leaf springs or considering replacements, it's often best to consult with a professional to ensure you select the right type and maintain optimal performance and safety.

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

Application:

Leaf springs are used in both trailers and trucks to handle the demands of heavy loads and provide a smooth ride. Their applications can vary depending on the type of vehicle, its intended use, and the specific requirements of the load it carries. Here’s a breakdown of their applications:

Truck Leaf Spring Applications:

Heavy-Duty Trucks:

Purpose: Designed to support and stabilize heavy loads, such as in commercial trucks, dump trucks, and tow trucks.

Features: Typically heavier-duty, with multiple layers of leaf springs to handle high stress and provide improved durability and load distribution.

Off-Road Trucks:

Purpose: Used in vehicles that operate in rough or uneven terrain, like construction trucks and off-road vehicles.

Features: Heavy-duty leaf springs often paired with shock absorbers to handle the shocks and stresses of off-road driving.

Pickup Trucks:

Purpose: For everyday use and light to moderate hauling, including transporting cargo or towing trailers.

Features: Leaf springs are designed to balance comfort and load capacity. Upgrades might be available for those needing additional support or improved ride quality.

Utility Trucks:

Purpose: Used in service vehicles like utility and maintenance trucks that need to carry tools and equipment.

Features: Leaf springs provide the necessary support for the added weight of tools and equipment while ensuring stability.

Trailer Leaf Spring Applications:

Utility Trailers:

Purpose: For carrying various loads, from landscaping equipment to small machinery.

Features: Typically use leaf springs that balance flexibility and load-bearing capacity. They may include single or multi-leaf designs depending on the load requirements.

Cargo Trailers:

Purpose: Designed for transporting goods and materials, often over long distances.

Features: Leaf springs in cargo trailers are selected for durability and to handle varying load weights. They may feature additional components like shock absorbers for smoother rides.

Travel Trailers:

Purpose: Used for recreational vehicles (RVs) and travel trailers, which need to handle both the weight of the trailer and provide a smooth ride.

Features: Often equipped with leaf springs that offer a balance between load capacity and ride comfort, sometimes complemented with additional suspension components.

Boat Trailers:

Purpose: To transport boats of various sizes and weights.

Features: Leaf springs on boat trailers are designed to support the weight of the boat and handle the stresses of launching and retrieving, often featuring rust-resistant materials due to exposure to water.

Choosing the Right Leaf Springs:

Load Capacity: Ensure the leaf springs are rated for the maximum load you intend to carry. Overloading can lead to premature wear and failure.

Ride Quality: For trucks and trailers that are used for heavy-duty applications, consider leaf springs that offer a balance between load support and ride comfort.

Terrain and Use: Off-road vehicles might require more robust, heavy-duty leaf springs compared to those used in regular road transport.

Installation and Maintenance:

Professional Installation: For optimal performance and safety, leaf springs should be installed by professionals, especially if upgrading or replacing them.

Regular Checks: Inspect leaf springs regularly for signs of wear, such as cracks or broken leaves. Proper maintenance extends their lifespan and ensures safe operation.

Understanding the specific needs of your vehicle and its load will guide you in selecting the appropriate leaf springs to ensure both performance and safety.