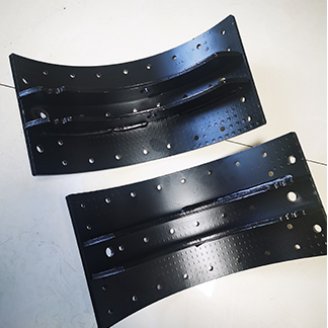

Leaf Spring for Truck

20+ Years of experiences (since 2005)

Implementing IATF 16949-2016

Implementing ISO 9001-2015

Quality standards: GB/T 19844-2018, GT/T 1222-2007

Leaf length tolerance (mm): ±2 (Exceed spring industry standard ±3)

Camber tolearance (mm): ≤±6 (Exceed spring industry standard ±7)

Fatigue life ( cycles): >120,000+ (Exceed spring industry standard 100,000 cycles)

Product Description:

Product Parameters:

Parameter | Sign | Chord | Chord | Total Pieces | Thickness/pc(mm) | Width(mm) | Assembly | |

XH3-90-10 | 1130 | 80 | 10 | 13 | 90 | 71 | ||

XH13-90-13 | 1130 | 80 | 13 | 13 | 90 | 79 | ||

XH12-100-12 | 1135 | 80 | 12 | 12 | 100 | 83 | ||

XH16-75-10 | 1110 | 90 | 10 | 16 | 75 | 71 | ||

XH16-90-9 | 1115 | 80 | 9 | 16 | 90 | 79 | ||

XH12-900-12A | 1200 | 120 | 12 | 12 | 100 | 95 | ||

XH16-90-9A | 1130 | 70 | 9 | 10 | 90 | 82 | ||

XH13-90-9A | 1120 | 80 | 9 | 13 | 90 | 62 | ||

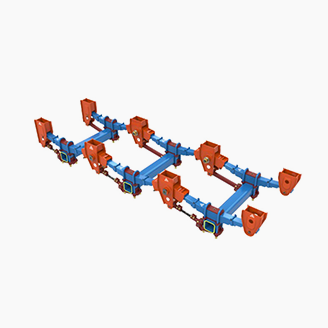

Application:

Leaf springs are extensively used in trucks due to their ability to handle heavy loads and provide robust suspension support. Here are some specific applications of leaf springs in trucks:

Load Handling: One of the primary reasons leaf springs are used in trucks is their capability to support and distribute heavy loads effectively. Trucks are often used for transporting goods, construction materials, or equipment that require a suspension system capable of carrying significant weight without compromising stability or safety.

Durability: Trucks are subjected to rough terrain, varying road conditions, and heavy usage. Leaf springs, made from durable materials such as tempered steel, are designed to withstand these challenges over long periods without significant degradation in performance.

Off-Road Capability: Many trucks are used in off-road environments where the terrain can be rugged and unpredictable. Leaf springs provide robust suspension support that helps trucks navigate uneven surfaces, bumps, and obstacles while maintaining stability and control.

Towing and Hauling: Trucks often tow trailers or haul heavy loads, placing additional stress on the suspension system. Leaf springs are chosen for their ability to handle these dynamic loads effectively, providing necessary support and minimizing sagging or instability.

Cost-Effectiveness: Leaf springs are relatively economical to manufacture and maintain compared to more complex suspension systems. This cost-effectiveness makes them a practical choice for commercial trucks and fleet vehicles where reliability and operational costs are critical considerations.

Customization and Adaptability: Leaf springs can be customized in terms of thickness, number of leaves, and design to suit specific truck applications and load requirements. This adaptability allows manufacturers and truck owners to optimize suspension performance based on their operational needs.

Maintenance: While requiring periodic inspection and maintenance, leaf springs are generally straightforward to service compared to other suspension types. Routine checks for wear, lubrication, and potential damage help ensure optimal performance and longevity.

In summary, leaf springs play a crucial role in truck applications by providing robust suspension support, durability, and load-carrying capacity. Their widespread use in various types of trucks highlights their effectiveness in meeting the demands of heavy-duty transportation and commercial operations.