American Brake Drum Axle for Truck Semi Trailer

20+ years of experiences (since 2005)

Implementing ISO 9001-2015

Quality testing by an independent laboratory

Warranty: 12 months since shipping date

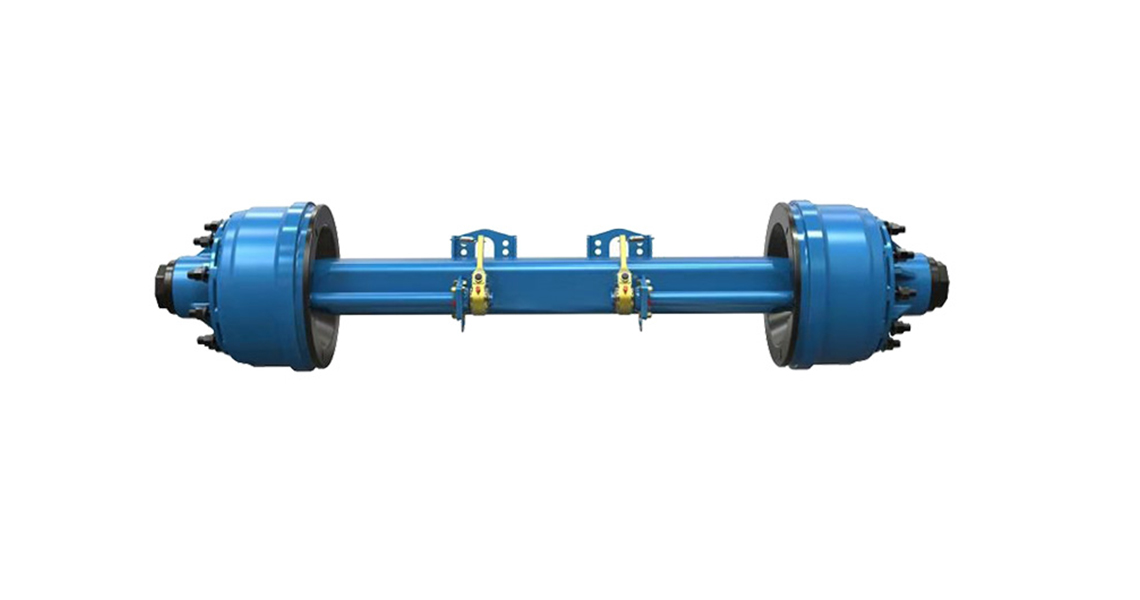

Fatigue life: 1,700,000 cycles

Bearing position machining precision (Dia.): 0~0.025mm

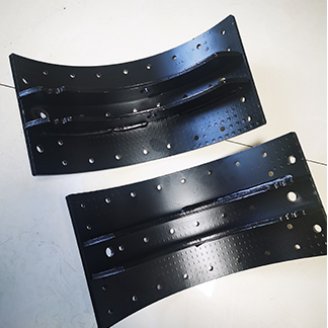

Brake shoe: cylindrical grinding

Both ends of the beam are processed at the same time

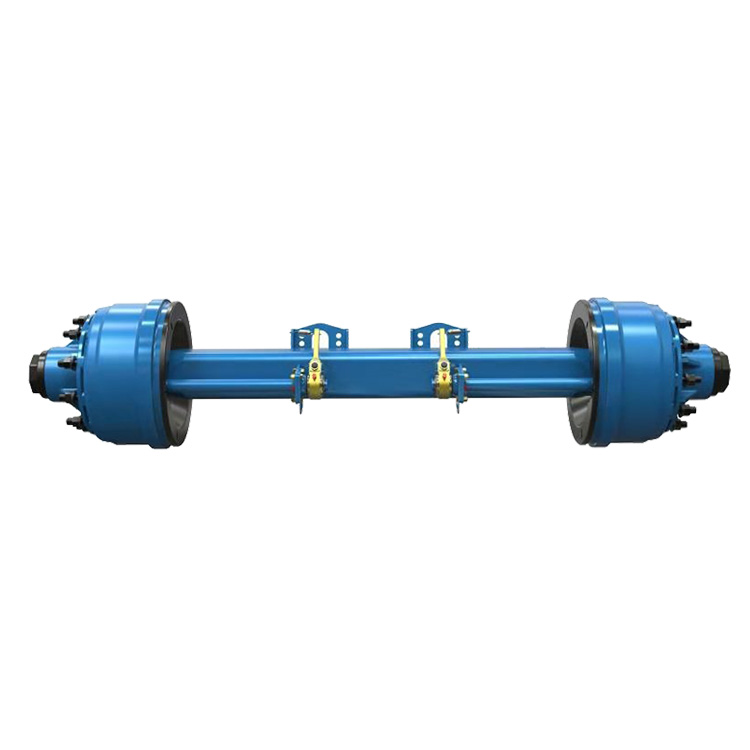

American Brake Drum Axle for Truck Semi Trailer

American brake drum axle for a truck semi-trailer typically refers to an axle assembly designed to support heavy-duty trucks and trailers used in the transportation industry. Here are some key points about such axles:

1. Purpose: The brake drum axle is a crucial component that connects the wheels of the semi-trailer to the chassis. It allows for the transmission of power from the engine and braking forces from the brake system to the wheels.

2. Design: American brake drum axles are designed to withstand high loads and rigorous conditions encountered in long-haul transportation. They are typically made from high-strength materials such as forged steel to ensure durability and reliability.

3. Braking System: These axles are equipped with brake drums, which are essential for the braking system of the semi-trailer. Brake drums provide the surface against which brake shoes press to slow down or stop the vehicle.

4. Variants: There are various types of brake drum axles available, including straight axles and drop axles, depending on the specific application and trailer configuration.

5. Maintenance: Proper maintenance of brake drum axles is critical for safety and performance. This includes regular inspection of brake components, lubrication, and ensuring proper alignment and torque specifications.

6. Manufacturers: Several manufacturers produce brake drum axles suitable for American trucks and trailers, each offering different specifications and features to meet various operational requirements.

Product parameters:

Type | Max Capacity | A/B(MM) | C(MM) | E*F*T(MM) | L3(MM) | L2(MM) | L1(MM) | L3(MM) | Weight(kg) |

XH-14-01 | 14 | 88.9/88.9 | UN3.48-12 | 150*150*12.5 | 390 | 1430 | 1644 | 2108 | 120 |

XH-15-01 | 15 | 99.9/88.9 | UN3.48-12 | 150*150*15 | 396 | 1835 | 1664 | 2128 | 130 |

XH-16-01 | 16 | 99.9/88.9 | UN3.48-12 | 150*150*16 | 354 | 1266 | 1664 | 2128 | 140 |

XH-20-01 | 20 | 110/88.9 | UN3.48-12 | 150*150*18 | 354 | 1264 | 1700 | 2173 | 160 |

Application:

The application of American brake drum axles in truck semi-trailers is crucial for the safe and efficient operation of heavy-duty vehicles in various industries such as logistics, construction, and agriculture. Here’s how these axles are applied:

1. Heavy-Duty Transportation: Brake drum axles are primarily used in heavy-duty trucks and semi-trailers designed to transport large payloads over long distances. These vehicles are integral to logistics and supply chain operations, where reliability and durability are paramount.

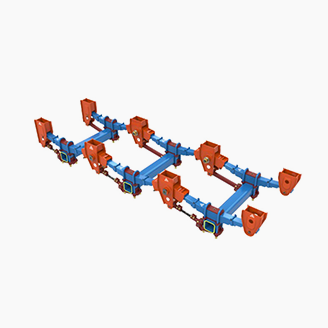

2. Load Handling: The axle assembly supports the weight of the semi-trailer and its cargo. It is designed to handle significant loads and distribute weight evenly across multiple axles in tandem configurations.

3. Braking System Integration: Brake drum axles integrate with the vehicle’s braking system. The brake drums attached to the axles provide a surface against which brake shoes or pads press to create friction and slow down or stop the vehicle safely.

4. Versatility: These axles are versatile and can be configured for different types of trailers, including flatbeds, refrigerated trailers, tankers, and specialized trailers for specific industries like construction or forestry.

5. Durability and Reliability: Designed with robust materials such as forged steel, American brake drum axles offer durability and reliability under challenging conditions. They withstand frequent braking, heavy loads, and varying road conditions encountered during long-haul transportation.

6. Maintenance Requirements: Regular maintenance of brake drum axles is essential to ensure optimal performance and safety. This includes inspection, lubrication, adjustment of brakes, and replacement of worn-out components to prevent failures that could lead to accidents or downtime.

7. Regulatory Compliance: Axles used in commercial vehicles must comply with safety and performance regulations set by authorities such as the Department of Transportation (DOT) in the United States. Manufacturers ensure their products meet these standards to ensure roadworthiness and legal compliance.