Product description:A manual slack adjuster is a device used in air brake systems on vehicles, such as trucks and buses, to adjust the clearance between the brake shoes and the brake drums. This adjustment is necessary to ensure proper braking performance and to prevent excessive wear on the brake components.To adjust a manual slack adjuster:Park the vehicle on a level surface and chock the wheels to prevent it from rolling.Locate the manual slack adjuster on the brake assembly.

Contact Now

Product description:The slack adjuster is the mechanical connection between the brake chamber pushrod and the camshaft on a cam brake. It is an important component for transmitting braking force and compensating the design gap between the brake lining and brake drum.Manual slack adjuster:The manual lash adjuster is an adjustment arm for manually adjusting brake lash. It is by far the most commonly used Slack moderator. It has the advantages of being cheap and easy to maintain, but it also has some disadvantages.

Contact Now

Product description:A manual slack adjuster for trailer is a device used in air brake systems on vehicles, such as trucks and buses, to adjust the clearance between the brake shoes and the brake drums. This adjustment is necessary to ensure proper braking performance and to prevent excessive wear on the brake components.To adjust a manual slack adjuster:1.Use a proper tool, such as a slack adjuster wrench, to turn the adjusting nut in the appropriate direction to either increase or decrease the slack.

Contact Now

Product description:An automatic slack adjuster is a vital component of a truck's air brake system. It is designed to maintain the appropriate amount of slack in the brake system as brake linings wear down over time. This helps to ensure that the brakes operate effectively and safely.When considering an automatic slack adjuster for your truck, there are a few factors to keep in mind:Compatibility: Ensure that the automatic slack adjuster is compatible with your truck's make and model.

Contact Now

Product description:Types: There are different types of automatic slack adjusters available, including standard automatic slack adjusters and self-setting automatic slack adjusters. Each type has its own features and benefits, so it's important to choose the one that best fits the specific requirements of your truck.Installation and Maintenance: Proper installation and regular maintenance of automatic slack adjusters are crucial for their effective operation.

Contact Now

Product description:A manual slack adjuster for a truck is a device used to adjust the clearance between the brake shoes and the brake drums in the air brake system. Proper adjustment of the slack adjuster is essential for maintaining optimal braking performance and ensuring the safety of the truck and its occupants.When adjusting the manual slack adjuster on a truck, follow these steps:1.Park the truck on a level surface and chock the wheels to prevent it from moving.2.Locate the manual slack adjuster on the brake assembly.

Contact Now

Product description:The automatic slack adjuster is a vital component of a commercial vehicle's air brake system. It is designed to maintain proper brake shoe-to-drum clearance as the brake linings wear down.

Contact Now

Product description:A semi-trailer brake adjuster, like a manual slack adjuster, is a component used to adjust the brake clearance in the air brake system of a semi-trailer. Proper adjustment of the brake system is crucial for maintaining safe and efficient braking performance while hauling heavy loads on the road.Here are steps to adjust the brakes on a semi-trailer using a manual slack adjuster:Park the semi-trailer on a level surface and make sure it is securely chocked to prevent any movement.Locate the manual slack adjuster on the brake assembly.

Contact Now

Product description:self-adjusting slack adjusters are important safety components in commercial vehicles equipped with air brake systems, providing automatic adjustment of brake shoe clearances to ensure reliable and effective braking performance.

Contact Now

Product description:Automatic slack adjusters are critical components in a truck's air brake system. Here's how they function and their importance in maintaining proper brake performance:Function: Automatic slack adjusters are designed to automatically adjust the brake shoe clearance as the brake linings wear down over time. This self-adjustment ensures that the brakes maintain the correct amount of clearance, allowing for optimal brake performance and safety.Safety: Properly adjusted brakes are essential for safe operation of a truck.

Contact Now

Product description:S-Camshafts are made to the highest standards. We use premium high-carbon HRC 45 tool grade steel for our s-camshaft brake parts, which include the journal and cam head. This high-quality steel can withstand even the harshest cold conditions found in the north of Canada and has been proven to last longer in milder road conditions.Operation: When brake air pressure is applied, it pushes the slack adjuster, which, in turn, rotates the S-camshaft.

Contact Now

Product description:The S-camshaft is a crucial component of a trailer's air brake system. It is responsible for transferring force from the air brake chamber to the brake shoes, causing them to press against the brake drum and create friction to slow down or stop the trailer. The S-camshaft is shaped like an "S," hence its name, and is typically mounted on the axle of the trailer.Key points about S-camshafts for trailers:1.Operation: When brake air pressure is applied, it pushes the slack adjuster, which, in turn, rotates the S-camshaft.

Contact Now

Product Description:Trailer landing gear, often referred to as landing legs, is a vital component of semi-trailers, providing support and stability when the trailer is detached from a tractor. Here’s a closer look at its features, types, and benefits:FeaturesSupport Legs: Typically consists of two adjustable legs, one on each side of the trailer's front.Crank Mechanism: Many landing gears use a hand crank to extend and retract the legs.

Contact Now

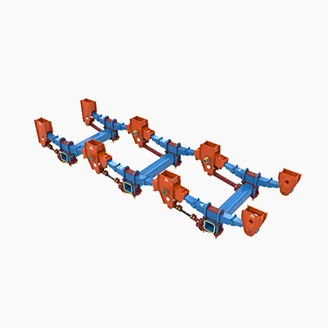

American Type Axle:American type semi-trailers typically use axles that are designed for heavy-duty applications. The axles are usually selected based on the weight capacity and specific requirements of the trailer. Some common types of axles used in American semi-trailers include:Standard Axles: These are traditional axles with a fixed weight capacity. They are commonly used in trailers with moderate loads.Tandem Axles: Tandem axles consist of two axles placed side by side.

Contact Now

American Type Axle:American semitrailers typically use axles designed for heavy duty applications. Axles are usually selected according to the weight capacity and specific requirements of the trailer. Some common axle types used in American semitrailers include:Standard axles: These are conventional axles with a fixed weight capacity. They are usually used in trailers with moderate loads.Tandem axle: Tandem axle consists of two axles placed side by side.

Contact Now

Spoke Type Axle:A spoke type axle refers to a specific design feature found in some types of trailer axles. Instead of a solid or tubular axle, a spoke type axle consists of multiple rods or beams connected in a spoke-like pattern to support the weight of the trailer and its cargo.

Contact Now

Product description:The brake shoe is the frictional part of the drum brake, which bears the thrust of the actuator, the normal force and tangential force of the brake drum, and the supporting reaction force, and should have appropriate stiffness.

Contact Now

Truck brake shoes are an important part of your truck's braking system. Here is some key information about them:1. Function: Brake shoes are part of a drum brake system and are common in heavy-duty vehicles such as trucks. When the brake pedal is pressed, hydraulic pressure pushes the brake shoes against the inner surface of the drum, creating friction that slows and stops the truck.2. Construction: They are usually made of a heat-resistant friction material bonded or riveted to a metal backing plate.

Contact Now

Product description:A semi trailer brake shoe is a component of the brake system in a semi trailer. Technical parametersBrake size: 16.5 inches in diameter.Brake width: 7 inches.Friction material grade load: 20,000 pounds or 23K grade (different products may vary).Friction material connection method: Riveted.Product parameters:Item noBRΦ1ΦA1+A2T1T2Dia.of HoleNo.of HoleXHBC/36/1180205Φ26.2Φ36.4317.785Φ8.520XH4515180203Φ27.5Φ19.5323.8585Φ6.532XH4515E180203Φ27Φ19.1323.8585Φ6.532XH4515Q180205Φ32Φ19.2323.8585Φ6.532XH4551220205Φ27.5Φ19.5323.8585Φ6.732XH4551E220203Φ27Φ19.1323.8585Φ6.532XH4551Q22

Contact Now

Product Description: A high-quality leaf spring is characterized by several key features and attributes that distinguish it from standard or lower-grade leaf springs. Here are the characteristics that define a high-quality leaf spring:Material Quality: High-quality leaf springs are typically made from premium materials such as alloy steels or composite materials. These materials offer superior strength, durability, and resistance to fatigue compared to lower-quality steels.Manufacturing Standards: They are manufactured using advanced processes and stringent quality control measures.

Contact Now

Product Description:A high-performance leaf spring typically refers to a leaf spring that is designed and manufactured to offer superior performance characteristics compared to standard leaf springs. Leaf springs are used in vehicles to support the weight, absorb shocks, and maintain stability.Here are some key features and considerations for high-performance leaf springs:Material: They are often made from high-quality materials such as alloy steels or composite materials.

Contact Now

Product Description: A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. It consists of a series of curved, narrow, flat plates or "leaves" of varying lengths stacked on top of each other. These leaves are held together in the center by a bolt or clamp and are attached at both ends to the vehicle frame and axle.The primary function of a leaf spring is to absorb and distribute the weight and shocks encountered during vehicle movement.

Contact Now

Product Description:Heavy-duty truck leaf springs are crucial components in a vehicle's suspension system, especially for trucks and other heavy-duty vehicles. They help support the vehicle's weight, absorb shocks, and maintain stability and control.Here’s a bit more detail on them:Design and Function:Leaf Spring Structure: They consist of several layers (or leaves) of metal, typically spring steel, stacked together. The layers are curved and held together with clamps.

Contact Now

Product Description: Truck suspension systems, particularly those utilizing leaf springs, are critical for supporting heavy loads, ensuring stability, and maintaining control over varied terrain. Here’s an in-depth look at the components and application of leaf springs in truck suspension:Components of Truck Leaf Spring Suspension:Leaf Springs:Multi-Leaf Springs: Most trucks use multi-leaf springs, which consist of several layers (or leaves) of tempered or hardened steel stacked together.

Contact Now